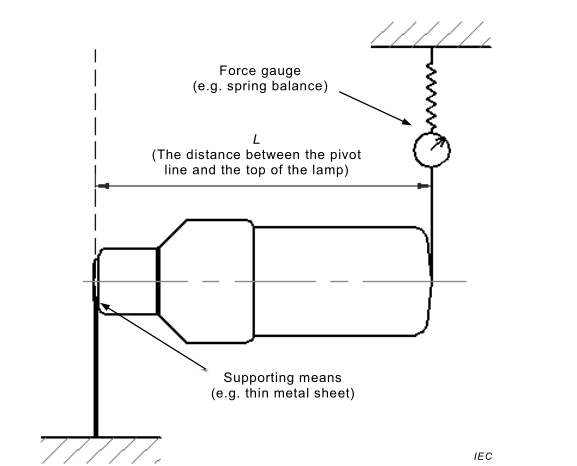

IEC 60968-Figure 3 Test Arrangement For Bending Moment Imparted By The Lamp At The Lampholder

IEC 60968-Figure 3 Test Arrangement For Bending Moment Imparted By The Lamp At The Lampholder

- Model:

IEC 60968-Figure 3 Test Arrangement For Bending Moment Imparted By The Lamp At The Lampholder

IEC 60968-figure 3 Test arrangement for bending moment imparted by the lamp at the lampholder

Samples and Restrictions:

Semi-luminaires intended for connection to Edison screw or bayonet lampholders

Application:

It is used to test the bending moment effect of the semi-luminaires on the lampholders, in order to prevent the damage of the lampholders from being damaged by excessive bending moment.

Test Principle:

Using a push-pull force gauge to connect with a semi-luminaire through a flexible cord, the force of the free bending of the luminaire is measured, and the actual bending moment value is calculated by multiplying the force arm, compared with the standard requirement.

Technical Parameters:

| Digital display force gauge | Digital display, force range: 0-100N, resolution 0.1N |

| Measurable length of semi-luminaires | 0-400mm |

Figure 3 – Sample test arrangement for bending moment imparted by the lamp at the lampholder

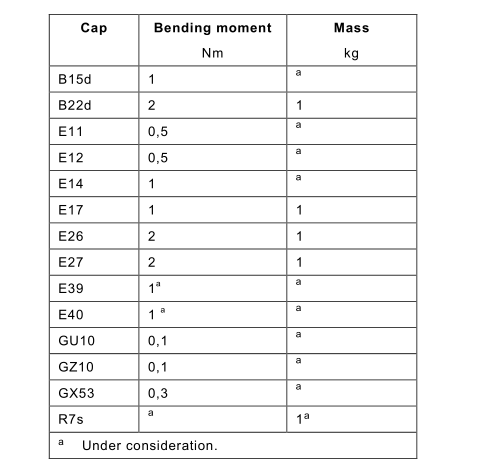

The mass as given in Table 2 shall not be exceeded.

Table 2 – Bending moments and masses

TESTING AND MEASURING EQUIPMENT/ALLOWED SUBCONTRACTING

IEC 62560 Edition 1 2011 – A1:2015

Self-ballasted LED lamps for general lighting services by voltage > 50 V - Safety specifications

| Clause | Measurement/testing | Testing / measuring equipment / material needed | Price (RMB) | Subcontracting |

| 5.3 | Marking | Hexane, | R | |

| water, | ||||

| piece of cloth | ||||

| 6.1 | Cap interchangeability - Table 1 | Gauges according to IEC 60061-1 and IEC 60061-3 | R | |

| 6.2 | Bending moment and mass imparted by the lamp at the lamp holder | Test finger with indicating device and with force meter, | R | |

| Weighting device | ||||

| 7 | Protection against accidental contact with live parts | Standard Test finger (IEC 60529) , | R | |

| IEC 60061-3, sheet 7006-51A for E27 caps | ||||

| IEC 60061-3, sheet 7006-55 for E14 caps | ||||

| Mega ohmmeter, | ||||

| High Voltage transformer | ||||

| 8.2 - 8.3 | Insulation resistance and electric strength after humidity treatment | Humidity cabinet, | R | |

| Mega ohmmeter, | Use same as Clause 7 | |||

| High Voltage transformer | Use same as Clause 7 | |||

| 9.2.1 | Torsion resistance of unused lamps | Holder for torque test Figure 3 and figure 4 | R | |

| 9.4 | Axial strength of Edison Caps | Gauges according table 4, | R | |

| dynamometer | ||||

| 10 | Cap temperature rise | Temperature test cap | R | |

| Temperature test draught-proof enclosure | ||||

| 11 | Resistance to heat | Heating cabinet, | R | |

| Ball pressure test apparatus | ||||

| 12 | Resistance to flame and ignition | Needle flame test apparatus, | R | |

| Glow-wire test apparatus | ||||

| 14 | Creepage distances and clearances | Digital calliper (or equivalent) | R | |

| 15 | Abnormal operation | Circuit shown in Figure 8 (for non-dimmable lamps on a dimmer or an electronic switch), | R | |

| test finger | ||||

| 17 | Photobiological safety | UV radiation test instruments / retinal blue light hazard test instruments (Equipment List of IEC/TR 62778:2012, Edition 1.0), | S | |

| Goniophotometric measurement system | ||||

| 18 | Ingress protection | IP X4 test equipment | R |