High Stability Electrodynamic Vibration Shaker System Computer Control EV103VT

High Stability Electrodynamic Vibration Shaker System Computer Control EV103VT

- Model:

High Stability Electrodynamic Vibration Shaker System Computer Control EV103VT

I. Product Application

Vibration test is a process of exciting or shocking some part or device to observe its reaction in real environment. Vibration test is widely applied in many fields, ranging from circuit board, airplane, ship, rocket, missile, automobile, household appliance and other industrial products.

Labtone can offer you the whole vibration and testing proposal, and provide you with the quality certificates of products according to national and international standards, including GB, GJB, UL, JIS, DIN, ISO, BS, MIL, IEC and ASTM standards.

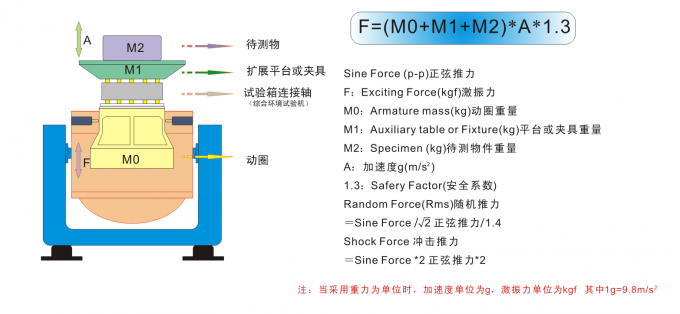

II. Type Selection Formula of Vibrator and Structural Diagram of Vibration Generator

① Test conditions provided by your company;

② Test types: sine sweep; random;

③ Frequency response range: 2 to 3000Hz

④ Formula: A(g)=(2πf)2Dcm/980≒A=0.002DmmF2 D=A/0.002F2

F=M(kg) ×A(g)

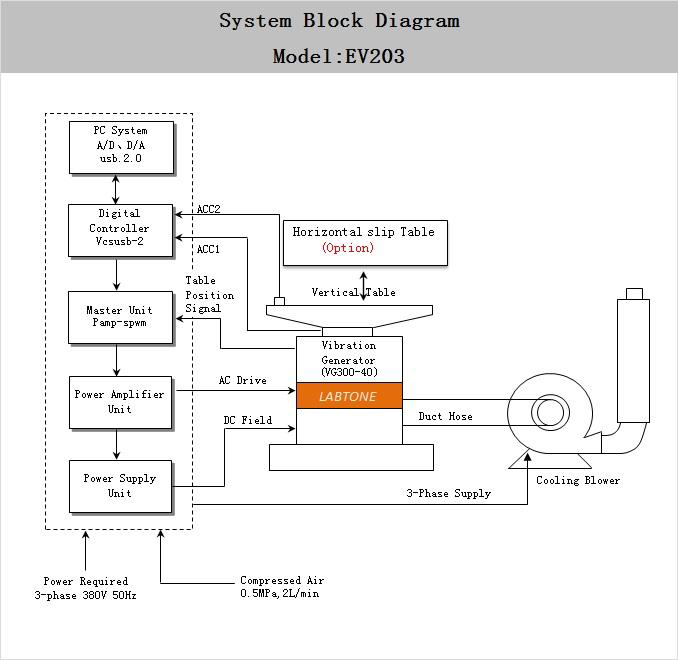

III. Principle Block Diagram of Equipment

Installation diagram of vibration tester

IV. Equipment Configuration

| Configuration | Qty. |

| 1. Vibration table | |

| VG300-25 electromagnetic vibration generator | 1 set |

| BL-300 cooling blower (including silencer) | 1 set |

| VT640 vertical extending table: 400*400MM | 1 set |

| Automatic centering system of armature | 1 set |

| 2. Digital switch power amplifier | |

| SA-3 digital switch power amplifier | 1 set |

| Servo protection system | 1 set |

| Excitation power supply | 1 set |

| 3. Digital vibration controller (integrated instrument cabinet) | |

| Master unit of digital vibration controller | 1 set |

| System acceleration sensor | 1 PCS |

| Control computer | 1 set |

| Control software installation disc | 1 set |

| 4. Attached accessories | |

| Extension cable and duct hose | 1 set |

| Operation instructions, inspection report, certificate, maintenance manual, etc. | 1 set |

| Attached special tools | 1 set |

| Vibration press rod / holddown strip fixture | 1 set |

V. Technical Parameter

| Parameters of VG1000-50 electromagnetic vibration generator | |||||||

| Max. sine exciting force | 300Kg.f peak | ||||||

| Max. random exciting force | 300Kg.f r.ms | ||||||

| Max. shock exciting force | 600Kg.f peak | ||||||

| Frequency range | 2~4000Hz | ||||||

| Max. displacement | 25 mm p-p | ||||||

| Max. velocity | 1.8m/s | ||||||

| Max. acceleration | 100G (980 m/s2) | ||||||

| Max. load (sine) F=M.A | |||||||

| 5G (49 m/s2) | 10G (98 m/s2) | 20G (196 m/s2) | 30G (294 m/s2) | ||||

| 57kg | 27kg | 12kg | 7kg | ||||

| Effective load(M1+M2) | 120 kg | ||||||

| Vibration isolation frequency | 2.5 Hz | ||||||

| Diameter of armature | Ф150 mm | ||||||

| Mass of armature | 3kg | ||||||

| Table screw | 13×M8 | ||||||

| Flux leakage | <10gauss | ||||||

| Allowable eccentric moment | 300N.m | ||||||

| Equipment dimensions | 750mm×560mm×670mm (excluding extending table) | ||||||

| Equipment weight | About 460Kg | ||||||

| SA-3K digital switch power amplifier | |||||||

| Output power | 4KVA | ||||||

| Output voltage | 100V | ||||||

| Output current | 30A | ||||||

| Amplifier efficiency | ≥90% | ||||||

| Switching frequency | 116KHz | ||||||

| Signal to noise ratio | ≥65dB | ||||||

| Noise | ≤70dB | ||||||

| Amplifier dimension | 720mm×545mm×1270mm | ||||||

| Servo protection system | |||||||

| Functions: | Temperature, air pressure, over-displacement, over-voltage, over-current, input under-voltage, external fault, control power supply, logic fault, input phase loss, etc. | ||||||

| Digital vibration controller VCS-2 | |||||||

| Hardware configuration: | 2-channel inputs, 1-channel outputs | ||||||

| Control computer | Original computer is provided with a 17” liquid crystal display and a keyboard / an optical mouse | ||||||

| Software | Chinese / English instructions are provided, and the software is available for time-domain and frequency-domain analysis, signal source and sine frequency sweep analysis, etc. It also can automatically generate WORD test report, display and store signal and data, and set testing parameters and analysis function. | ||||||

| Operating system | Windows 7/8 | ||||||

| Acceleration sensor LAB | Frequency range: 1 to 12000Hz Sensitivity: 30pC/g Temperature range: -24℃ to 250℃ | ||||||

| VT640vertical extending table | |||||||

| Material | Aluminum-magnesium alloy with surface hard anodized | ||||||

| Dimension | 400mm×400mm | ||||||

| Fixing hole | M8 durable and wear-resistant stainless steel screw sleeve | ||||||

| Frequency of use | Sine: 1000Hz; Random: 2000Hz | ||||||

| Weight | 15KG | ||||||

| BL-300 cooling blower (including silencer) | |||||||

| Blower power: | 1.1KW | ||||||

| Flow rate | 1404m3/h | ||||||

| Electrical requirements: | |||||||

| Power supply | AC three-phase 380V/50Hz, 15 KVA | ||||||

| Ground resistance | ≤4Ω | ||||||

VI. Introduction to Equipment Performance

6.1 Vibration table VG300-25

6.1.1 Armature

Vibration table is provided with cast and manually processed armature, photoelectric pneumatic load support system and dual-bearing axial guide. The dual-bearing guide has a special function. It has excellent durability and can reduce axial dynamic crossing and rotation in vibration test process.

6.1.2 Excitation coil

It is of double magnetic circuit structure with low flux leakage and uniform magnetic field.

6.1.3 Table surface

Advanced phosphating and automotive paint technologies are applied for the surface to resist wear and rusting for long time.

6.1.4 Table cooling

Intake air structure with low noise blower and improved table is applied, the excitation coil is of cellular duct, middle magnetic loop is of double-layer split duct, so new duct design is applied to enhance cooling effect.

6.2 SA digital switch power amplifier

MOSFET or IGBT technology with reliable performance is used for SA digital switch power amplifier.

a. High stability and reliability.

b. Consistency with “CE” standard requirements of EU.

c. The power amplifier has high signal to noise ratio as sine double-frequency pulse width modulation technology is used.

d. Switching efficiency is high as operating principle of the switching power supply is used.

e. Automatic electronic current sharing technology is used.

f. Good safety.

6.3 Servo protection system

It has complete protection functions, including grid overvoltage, under-voltage, phase loss, logic fault, power module conduction through, over-temperature, over-current output, overvoltage output, power supply drive, table over-displacement, table temperature, external interlocking, etc.

6.4 Vertical extending platform

The extending platform is usually used as a large installation platform of specimens which can be square, round or defined by users. In order to reduce dynamic impact on the extending platform, all extending platforms must be subject to analysis of modal frequency by modeling, and these platforms are generally made of magnesium alloy and attached with damping materials.

6.5 Automatic photoelectric centering system

It automatically adjusts position of the armature to keep it in balance state. The automatic centering system is used to ensure that the armature is in the center during loading and unloading process.

7. Introduction to digital vibration controller

The vibration controller is of advanced distribution structure system, and closed-loop control is achieved by DSP processor. PC is independent of control loop to ensure real-time and high efficiency of the control system so as to timely and rapidly respond to any changes of the test system, and ensure control stability and high precision. 32-bit floating-point DSP processor with primary frequency up to 300MHz and 24-bit resolution ADC/DAC are used for hardware in coordination with high precision floating-point digital filtering and low noise design technology of hardware circuit. The dynamic random control range of the controller is more than 90dB and the signal to noise ratio is more than 100dB.